Softner Plant

Recognising the need for advanced water softening technology, 'RUBI'. series of softeners incorporates the proven technique of counter flow regeneration, reducing the hardness slippages and giving you consistent quality of soft water. Applications cover the full spectrum of industrial, commercial, medical and agricultural users.

Applications

- Textiles

- Boiler Feed Water

- Pharmaceuticals

- Food Processing

- Breweries

- Hospitals

- Hotels,Laundries,Dairies

- Process Water For Industries

- Service Section

- Borewells

- Vehicle washes - cars to aircraft

- Ice plants

- Horticulture/Greenhouse

- Film processing Printing

|

|

Advantages

- Variety of cost effective standard models.

- Advanced selection software for optimal configuration

- Improved aesthetics & rugged design

- User-friendly, low maintenance & easy to install

- Simple distribution & collection Systems.

- Pre dispatch assembly Check

- Quick availability

WATER SOFTENING PROCESS |

|

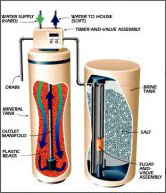

The objective of treatment in a base Exchange softener is to convert hardness forming salts of calcium and magnesium to soluble sodium salts.

Due to the low solubility of calcium and magnesium salts, they tend to precipitate and form scales when the temperature of water is increased.

Sodium salts are highly soluble and hence do not form hard scales. The hard water, to be treated, flows through bed of bead type polystyrene cation exchange resins in sodium form, which exchanges sodium ions with calcium and magnesium ions present in hard water.

It will be seen that resin retains the calcium and magnesium and releases equivalent amount of sodium to the water leaving the softener. After the softener has produced specified quantity of soft water, the softener should be regenerated with sodium chlorite. The reaction for the regeneration is given below.

It should be noted that the same softener could produce less amount of soft water between two regeneration, with increase in raw water hardness. The quantity of soft water may also get affected due to this increase / change in composition of raw water.

Technical Specification

Softner Plant are available in mild steel rubber/FRP lined up to 125000 LPH. With multiport valve available up to 15000 LPH

FRP vessels are available up to 1000 Dia. SS vessel are available for specific needs like pharmaceuticals industries, dairy, beverages food products & package drinking water with & without multiport valve up to 125000 LPH

|